Radio Frequency

SOLDERLESS MEASUREMENTS FOR MICROWAVE

Screening activities for space applications require extreme care during the manipulation of the EEE parts to be assembled on a spacecraft. This means that special attention must be paid to avoid damage to the parts, as well as any contamination by foreign materials. Soldering of the parts is hence totally prohibited, resulting in a huge challenge when the components under test operate at radio frequency and microwave frequency ranges. At these operating frequencies, the parasitic effects of the cables, adapters, and test fixtures become extremely important and must be correctly designed and compensated for.

When screening is performed at die level, all these problems are solved with the use of a probe station. This equipment is basically a high precision positioning system where several RF and DC probes are used to directly contact the pads on the die. Any inaccuracies in the test equipment, the cables and the probes themselves, are removed through the calibration process performed using adequate calibration standards prior to the electrical measurement. However, this calibration does not remove the effects produced by environmental conditions. For example, the light spot of the binoculars for the positioning of the probes may increase the power consumption of some silicon technologies. Hence, the whole set-up and its environment needs to be controlled during the measurement process.

If the components are already encapsulated, other fixturing options must be found. Usually two alternatives are employed: test sockets and customized test fixtures. Integrated circuit sockets are the most common solution when testing analogue and digital components. For RF and uW devices the use of customised test fixtures is preferred.

Sockets allocate the component and contact the printed circuit boards used for the measurements. However, at microwave frequencies the socket pins produce parasitic inductive and capacitive effects that may give rise to a mismatch of signals and increased insertion losses. High frequency sockets must be used which are specially designed to minimise these effects, and this increases the cost of the test set-up. In any case, for a precise characterization of the component, measured data should be de-embedded. De-embedding is the act of taking data that is measured in a test fixture and removing the effects of the fixture so that the data is accurate to reference planes. This requires performing an electromagnetic analysis and modelling process for the test fixture in advance.

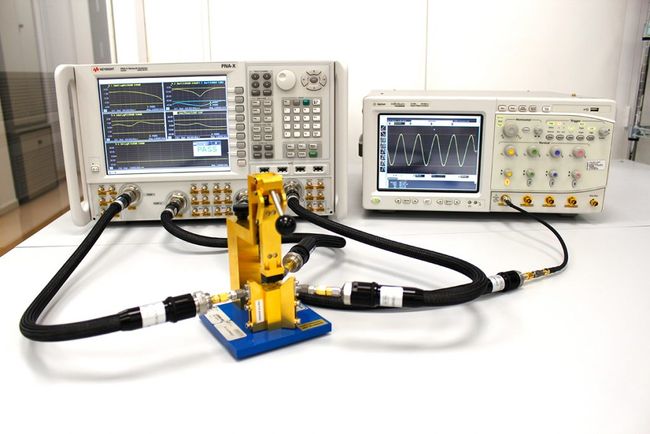

Customized test fixtures are an alternative to sockets. These are specifically designed for a specific component, together with an ad hoc calibration kit. In such test fixtures, the component is placed directly on the board as if it were to be soldered, but instead it is pressed to improve electrical contact. The pressure of the tool is calibrated to avoid damage to the component. The fixture is designed with 3D CAD design tools and paying special attention to the launches for a good matching of the connector and the transmission lines. In addition, when high power capability is required, additional thermal analysis may be performed on the test fixture under design. The test fixtures are manufactured with precision milling machines. Ad hoc calibration kits are designed to remove the effects of the fixture and place the reference plane of the measurements at the component.

Any fixturing solution is finally connected to the testing and measurement equipment using coaxial connectors and cables. Most electrical measurements are performed using a vector network analyser for S parameter characterisation.

However, other equipment may also be used, such as spectrum analysers, signal source analysers and digital signal analysers. The quality of accessories such as adapters, impedance tuners, attenuators, calibration kits and test cables is very important for accurate and repeatable measurements. For instance, the lack of phase stability of semi-rigid/flexible cables may affect the measured performance.

At Alter Technology, we can perform:

- S-parameter characterisation up to 50 GHz with the four-port N5245A PNA-X network analyser from Keysight Technologies, the world’s most integrated and flexible microwave test equipment for measuring both passive and active devices.

- VCO characterisation up to 7 GHz with the E5052B Signal source analyser which features many enhanced performance characteristics to offer the world’s highest measurement throughput and best usability in a single test set-up.

- Spectrum and harmonic characterisation up to 26.5 GHz with the E4407B Spectrum analyser. Specific options for noise figure and phase noise measurements are included in our device, expanding the capabilities of the signal source analyser.

- Time measurements up to 12 GHz with the 4-channel DSO81204B digital signal analyser with a sample rate of 40 GSa/s.